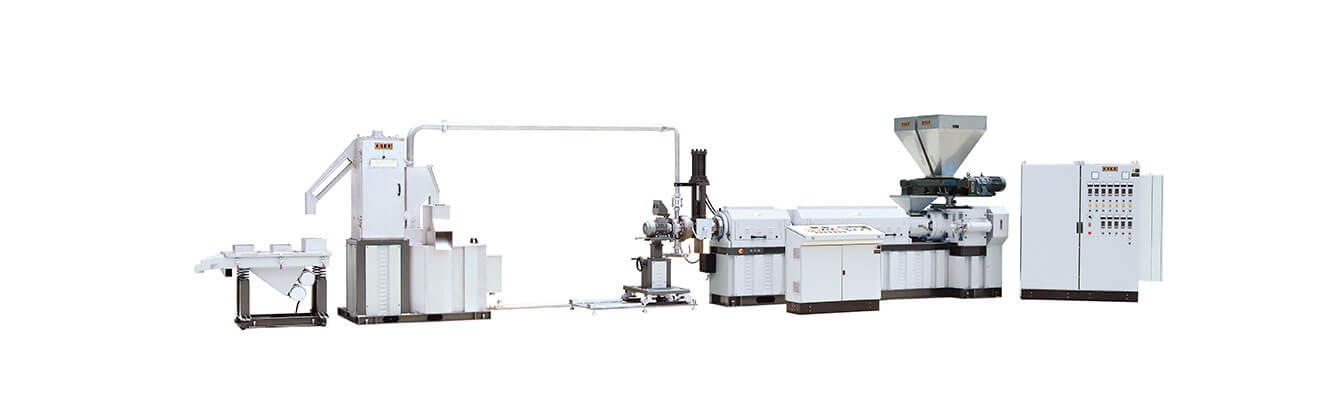

Single Screw Underwater Pelletizing Extrusion Line

Description

CYKF CK-S series Single Screw Underwater Pelletizing Extrusion Line can be applied to a wide range of applications. It is especially suitable for materials with high viscosity, low MI, and difficulty to be shaped, e.g., TPE and TPR.

Possible materials :

TPU, TPE, TPV, TPR, PP, PS, PLA, PVA, SEBS, EVA, Rubber, Hot-melt adhesive, Special resin, and Micro pellet, etc.

How It Works :

① Hopper ➜ ② Dosing feeder ➜ ③ Extruder ➜ ④ Underwater pelletizing system ➜ ⑤ Centrifugal dryer ➜ ⑥ Vibrating screening unit ➜ ⑦ Storage tankAfter raw materials are evenly mixed, they enter dosing feeder from hopper and delivered to plastic extruder for melting and kneading. The extruded melts are cut into pellets by underwater pelletizing machine. Since the cutting chamber is completely filled with process water, the melts are immersed in water as they come out from the die holes. The pellets are cooled and transported by water to downstream centrifugal dryer and screening units to become finished pellets.

-

Dosing feeder

Dosing feeder adopts counter-rotating twin screw design, it makes transportation of materials more stable. -

Extruder screw

Every section of the screw is designed according to material formulation. The purpose is to ensure the plastics are fully mixed to achieve high quality and high capacity extrusion performance. Our strict quality management guarantees good quality and long service life of the key component. -

Die

Die material and mold runner must be selected and designed according to physical properties and characteristics of plastics to avoid occurrences of uneven material flow rate, retention, excessive molding pressure, in-mold temperature increase, decomposition and carbonization or other situations that may damage material properties of plastics. -

Underwater pelletizing system

The die face of extruder is immersed in water. When melts exit the die holes, they are immediately cut into pellets by rotating knives, and cooled also transported by water to downstream equipment. Underwater pelletizing system is capable of handling virtually any type of polymer. -

Centrifugal dryer

The equipment can eliminate moisture on pellet surface. -

Vibrating screening unit

The machine body is made by stainless steel, it can filter out different size of pellets. -

Storage tank

Storage tank is an important part of extrusion line. The tank body is made by stainless steel and has different capacities for choice. Big bag filling machine or bagging machine are also available on request.

Features

1. Competitive throughput

The design of our single screw is based on material formulations. The purpose is to bring high-efficiency, high-throughput, and high-quality extrusion experiences to customers. We are proud to say that the production capacity of our single screw extruder is pretty competitive compared to the market.2. Sturdy and steady

Thanks to our strict policy in product quality that makes CYKF’s single screw extruder is able to maintain stable operation and high production throughput even under long time running. That’s why CYKF has won affirmation and praises from global customers.3. Diverse options

There are 3 models of our CK-S series. We also have CK-HS series for choice. Please contact us immediately for more product information.Specification

| Model | CK-S85 | CK-S100 | CK-S120 |

|---|---|---|---|

| Screw Diameter (mm) | 85 | 100 | 120 |

| L/D Ratio | 34 - 36 | 34 - 36 | 34 - 36 |

| Main Motor (kW) | 75 | 110 | 132 |

| Output (kg/hr) | 70 - 150 | 150 - 300 | 250 - 500 |

*Above data is based on TPU. Actual output depends on different materials.

*All specifications, design and characteristics shown above are subject to change without prior notice.