Medical Grade PVC Pelletizing Extrusion Line

Description

CYKF has good reputation in PVC extrusion. Our CK-DT Counter-rotating Twin Screw Extruder is especially designed for PVC production; the available screw diameter is between 55 to 130mm. Thanks to our technical team put long term effort on PVC extrusion technology which makes CYKF’s PVC extruder is competitive compared to other competitors. The high-efficient and durable PVC pelletizing machine can produce rigid PVC, soft PVC, medical grade PVC, UPVC, CPVC, and additives of foam or wood powders. It has outstanding performances that has earned highly praises from global customers.

Possible materials :

Especially for high-level medical grade PVC compounding.

How it works :

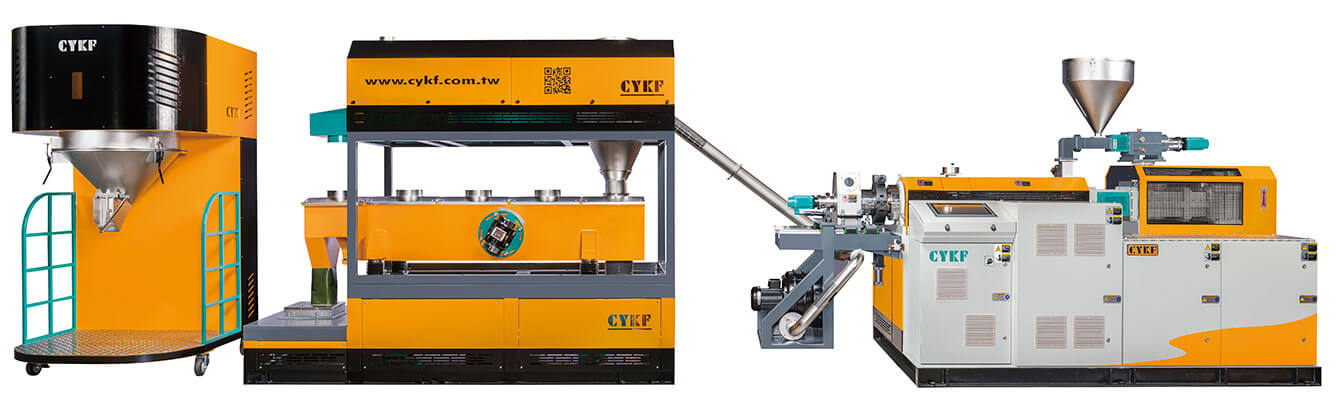

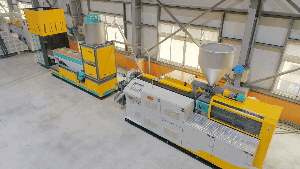

①Hopper (Force feeder/Dosing feeder) ➜ ②PVC extruder ➜ ③Die face pelletizing system ➜ ④Cyclone tank ➜ ⑤Vibrating cooler ➜ ⑥Storage tank

The mixed materials are delivered by hopper to PVC extruder for extrusion. The vacuum system of the PVC extruder can remove waste gas during production. The melts come out from the die and are cut into pellets by die face pelletizing system. The pellets are transported to cyclone tank by air and then cooled by vibrating cooler before delivering to storage tank.

-

Hopper

Force feeder and dosing feeder are available on request. Force feeder can evenly mix powders and effectively avoid bridging during material feeding. It is a standard equipment for producing soft PVC. Dosing feeder can make transportation of materials more stable.

-

Extruder screw

CYKF customizes extruder screws for high-level medical grade usage. From steel selection, machining accuracy to quality management, our strict standard procedures ensure superb quality and long service life of the extruder screws.

-

Die

CYKF estimates material properties and characteristics for selecting appropriate die material in combination with optimized runner design, that effectively avoids destruction on material properties due to excessive die temperature, uneven material flow rate, material jamming, excessive die pressure, decomposition and carbonization, etc. The die of the PVC extruder is designed with quick clamping in combination with linear guideway, making die open/close and die cleaning easy and fast.

-

Die face pelletizing system

The PVC pelletizing machine utilizes a special cutter hub, providing convenient cutter hub dismantling and calibration.

-

Cyclone tank

Cyclone tank can separate air and pellets and process initial cooling for pellets.

-

Vibrating cooler

Vibrating cooler removes adherent dust and cools plastic pellets evenly and rapidly.

-

Storage tank

The storage tank is the important device of extrusion systems. It is made by stainless steel and has different capacities for choice. Big bag filling machine and bagging machine are also available according to customers’ requirements.

Features

1. Continuous automatic production control system

The CK-DT PVC extrusion system for medical is equipped with an advanced high-level human-machine interface control system combined with the use of specific modules, including program detection control and synchronized proportional speed control to achieve continuous automatic control function. The fully functional automation system can help achieve optimal production. Traditional control panel is also available on request.

2. High quality pellet, high output

CYKF is capable of designing customized screws and barrels based on our 20 years experiences and knowledge in PVC. The excellent mixing behavior of CYKF’s PVC extruders can bring superb pellet quality as well as throughput to help customers have rapid returns on investment.

3. One-stop-shop integration service

CYKF builds complete plastic extrusion lines based on request. We integrate PVC extrusion system with appropriate upstream and downstream equipment to satisfy customer’s request. Our services include consulting, system integration, equipment installation and maintenance. We help customers make work easier and faster.

4. Durable and steady

The CK-DT medical series PVC extrusion lines are one of the most popular models of CYKF’s products. The stable extrusion system and high production capability have earned good reputations from customers worldwide.

5. Diverse options

There are 5 models of our CK-DT medical series. Different outputs are available. Please contact us immediately for more product information. Specification

| Model | CK-55DT | CK-75DT | CK-95DT | CK-110DT | CK-130DT | |

|---|---|---|---|---|---|---|

| Screw Diameter ( mm ) | 55 | 75 | 95 | 108 | 132 | |

| L / D Ratio | 24 | 24 | 22/24/30 | 24 | 24 | |

| Main Motor (kW) | 18 | 55 | 132 | 200 | 250 | |

| Output (kg/hr) | Soft | 25 - 50 | 60 - 120 | 150 - 300 | 200 - 450 | 500 - 800 |

| Rigid | 40 - 80 | 80 - 160 | 200 - 400 | 400 - 600 | 700 - 1000 | |

*Actual output depends on different materials.

*All specifications, design and characteristics shown above are subject to change without prior notice.